CNC Delem DA53T 6+1 axis WE67K-160T/4000mm hydraulic press brake machine

The electro-hydraulic servo CNC hydraulic press brake machine adopts an integral welding structure to ensure the high precision and stable performance of the machine tool. The CNC hydraulic bending machine adopts the principle of electro-hydraulic synchronization and has high synchronization performance. Equipped with imported servo motor to ensure the stability of machine tool operation. It can directly program the angle and has the function of angle compensation. The hydraulic system can achieve point-to-point pressurization, and can achieve rapid lowering during operation. The back gauge of the CNC hydraulic press brake machine can achieve precise positioning and fast running speed. The equipped Delem DA53T CNC system is easy to operate, has a high degree of automation and high precision in bending, and can automatically calculate the bending pressure and perform deflection compensation. With multi-step programming function, it can complete one-time processing of multi-step parts and improve production efficiency.

Feature

1.The back gauge adopts imported ball screw and linear guide, and the positioning accuracy of the back gauge is high.

2.Equipped with CNC DA53T 6+1 axies controller system,bend plates with high accuracy

3.CNC hydraulic press Brake macchine using fully closed-loop electro-hydraulic servo control technology

4.Keep the high accuracy between HIWIN ball screw and linear guide within 0.01mm

5.Equipped with gemany EMB tubing connector,simple structure and stable performance

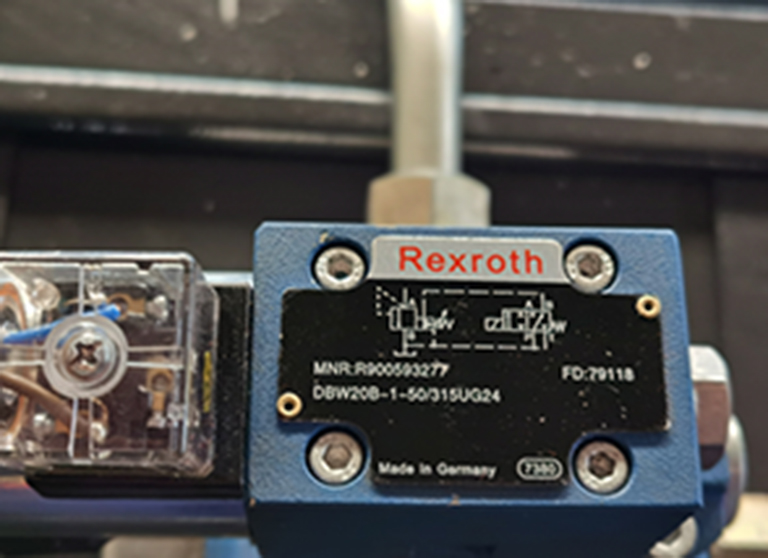

6.Germany Rexroth closed-loop electro-hydraulic servo synchronously controls the system

7.CNC hydraulic press brake machine can specialize designed according customer requirements

8.Laser photoelectric protection can be optional, high quality,safety,longlife

Application

Fully automatic CNC hydraulic press bake can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.

Parameter

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):4000mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):1600KN |

| Motor Power(kw):11KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:320mm | CNC or CN: CNC controller system |

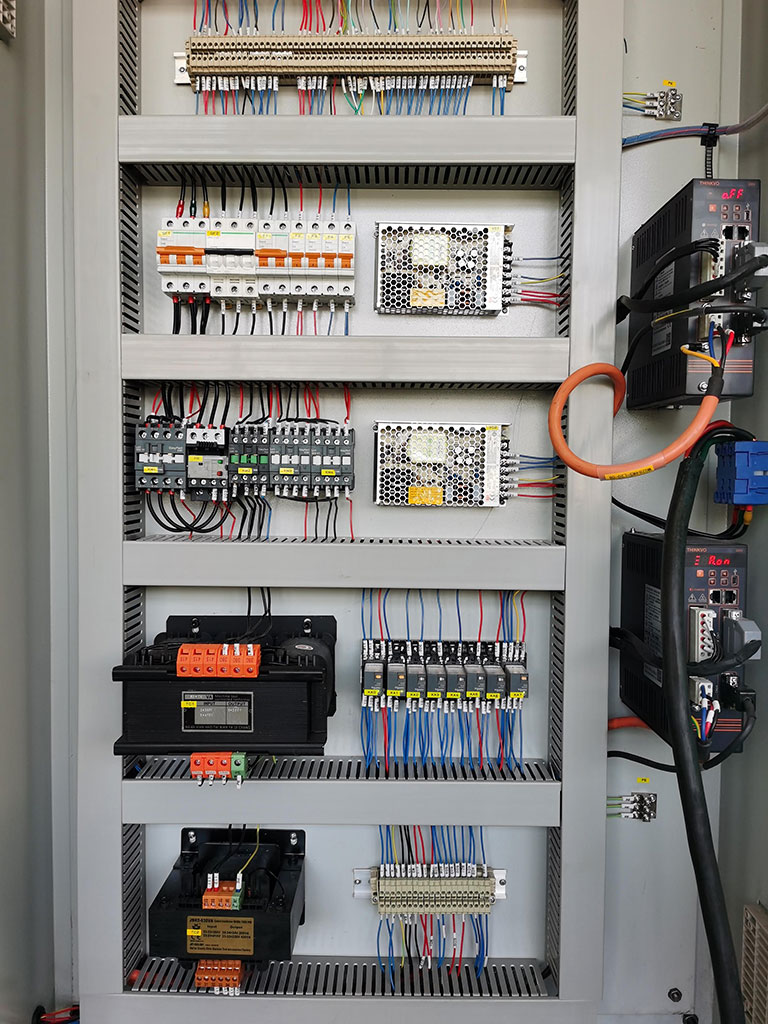

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

Machine Details

Delem DA53T controller

The DA53 CNC device has built-in control valve amplifier and PLC functions, which can be controlled not only by the torsion shaft synchronous bending machine, but also by the electro-hydraulic synchronous bending machine.

The panel mounting structure based on 4-axis control can be installed directly on the electric cabinet or in the suspension cabinet.With friendly user interface, TFT true color LCD display and menu drive, provide fast and concise programming tools.

Angle programming of the Y axis, table deflection compensation and pressure control are standard.

The da-53, based on the latest technology, provides a stable and reliable solution.It is equipped with USB interface, a great place to facilitate the product and mold quick backup.

DA - 53 features:

* standard 4+1 axis control

* dishes * single-drive parameter programming

* 10.4 "LCD true color TFT display

* table deflection compensation control

* mold library

* USB interface

* advanced Y-axis control algorithm to control both closed loop and open-loop valves

* built-in control valve amplifier

* PLC

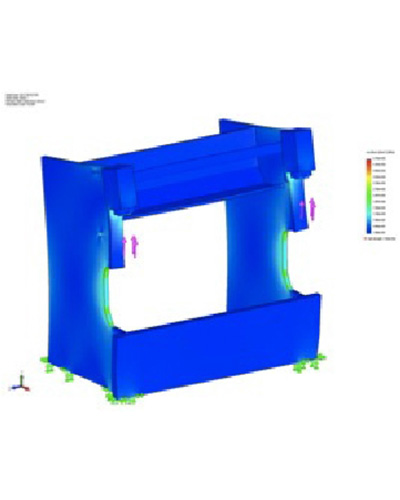

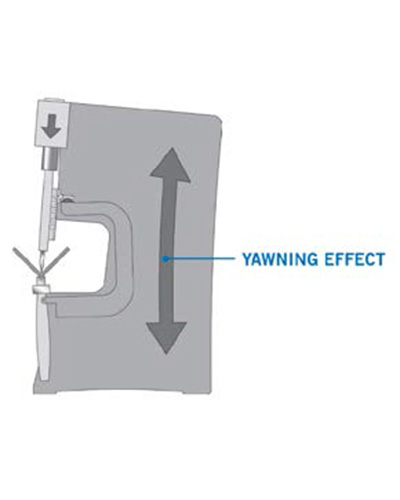

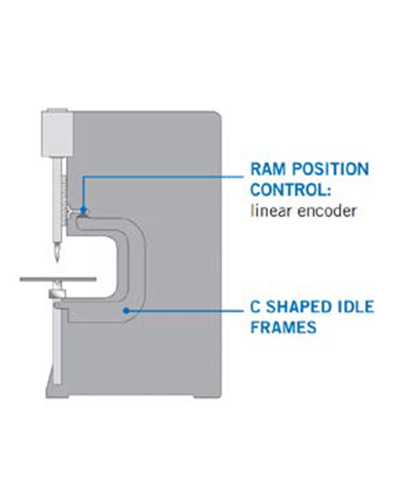

Overall welding

Overall welding the front workbench vertical plates and machine frames ensure there are no seam between vertical plates and bilateral wall plates.

■ Totally European streamlined design,Monoblock welded steel frame rigid & Heat Treated.

■ our machine designed according to the most modern design and performances point of view.

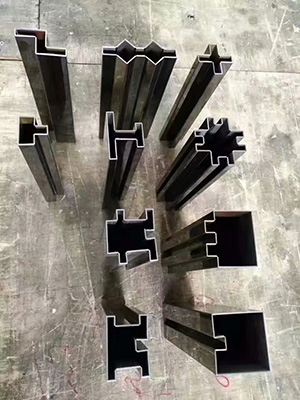

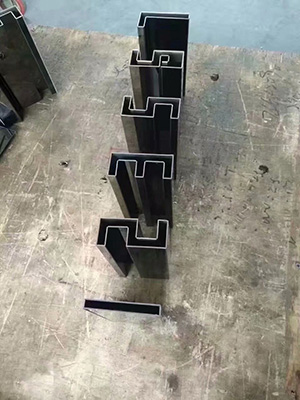

Moulds

Functional moulds can be optioanal,longlife,high quality

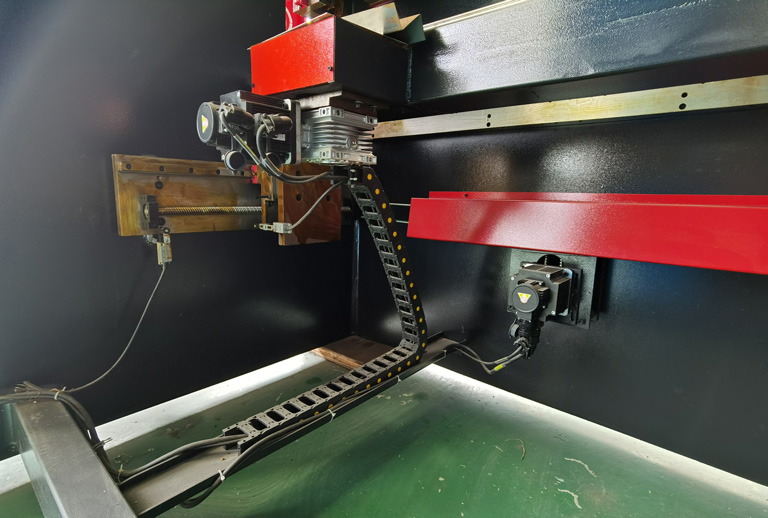

Ball screw and linear guide

High precision, high efficient and low noise

France Schneider electrics and DELTA inverter

France schneider electrics components, has longlife.

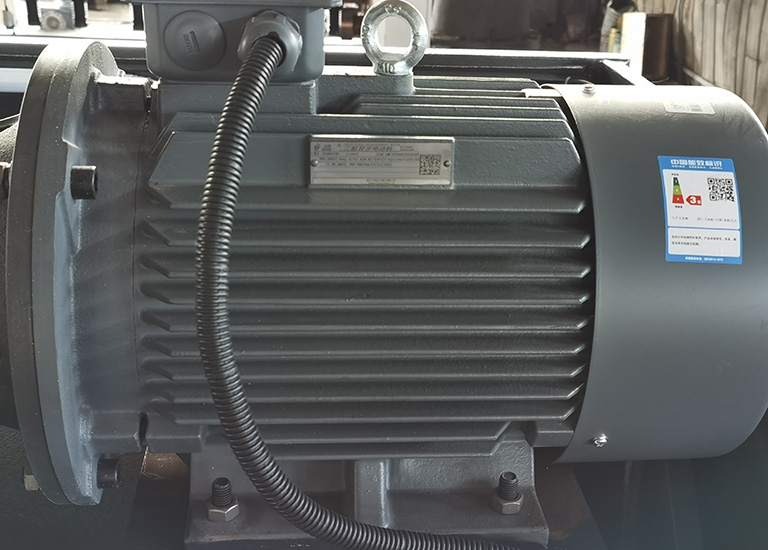

Siemens motor

Using siemens motor guarantee machine has long service life, can reduce nosie,with high stability

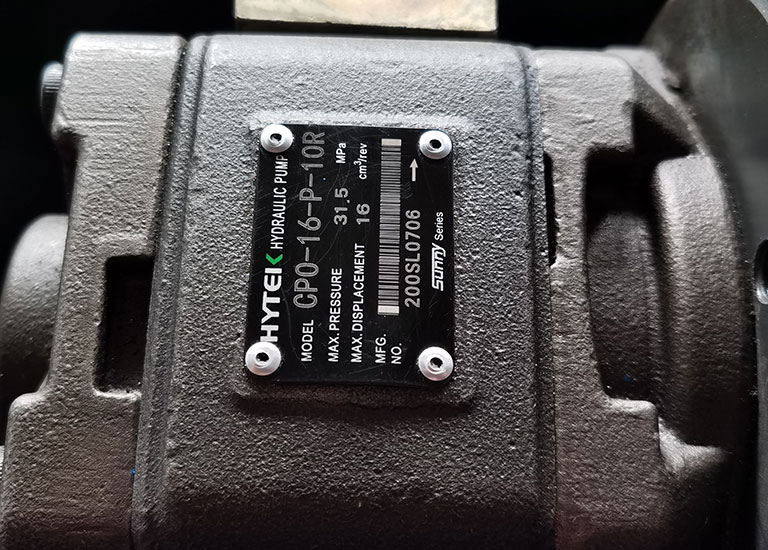

Sunny pump

Using Sunny pump guarantees the oil service life with low noise working

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability,integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid

Quick clampings

Upper die clamping tools are mechanical quick clamps,with higher safety when exchanging dies, easy operating

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction