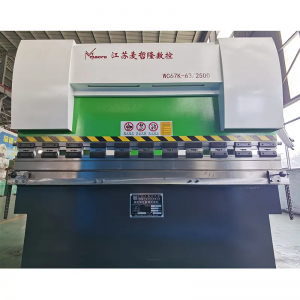

CNC Cyb Touch12 controller 4+1 axis WE67K-125T/3200mm hydraulic press brake machine

The electro-hydraulic servo CNC hydraulic press brake machine adopts servo motor as the power device, which meets the requirements of modern environmental protection and energy saving, and can process various metal workpieces with high efficiency and high precision. It adopts the overall welding structure and is equipped with a high-precision Cyb Touch12 numerical control system. It has the function of simulated bending and is easy to operate. The BOSCH hydraulic system imported from Germany is selected to ensure high working stability of the CNC hydraucli press brake machine. The compensation method of the workbench can be selected from mechanical compensation or hydraulic compensation, which ensures the good straightness and bending angle of the processed workpiece. The ball screw and linear guide are selected from Taiwan HIWIN high-end configuration. The numerical control system can automatically adjust the compensation amount, which is easy to operate and has a long machine life.

Feature

1.Fully automatic CNC hydraulic press brake machine bend sheet metal stainless steel plates,with high bending precision,high efficient,operating easy and safety

2.The welded steel structure of the whole machine ensures high precision and stability

3.Adopt Cyb Touch 12 visual operating system,with touch-screen,multi-functions and practical,easy operating.

4.4+1 axis CNC backguage,high accuracy can reach ± 0.01mm

5.With germany siemens main motor,schneider electric components from france

6.Equipped with linear guide rail and HIWIN ball screw , with high accuracy, can reach 0.01mm

7.Adopt electro-hydraulic servo control system, with high performance and high precision

8.CNC hydraulic Press Brake machine toolings use 40CrMo Materials, to ensure die with hardness, ensure die have long life.

Application

Fully automatic CNC hydraulic press bake can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.

Parameter

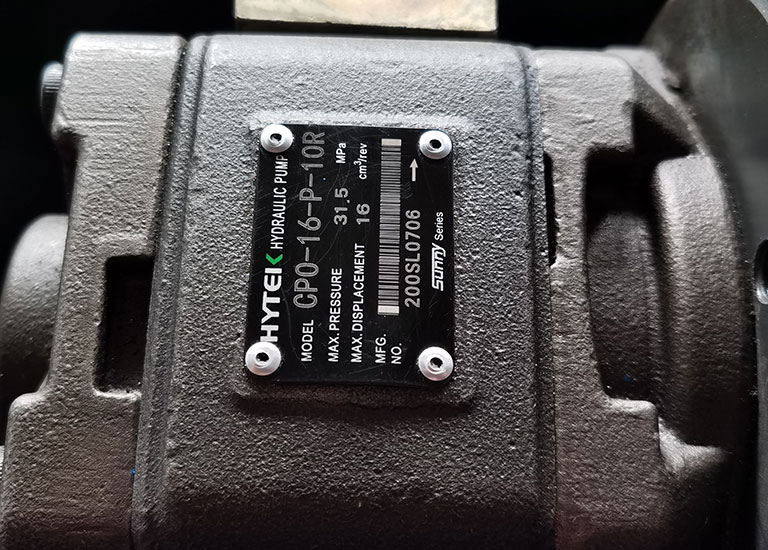

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):3200mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):1250KN |

| Motor Power(kw):7.5KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

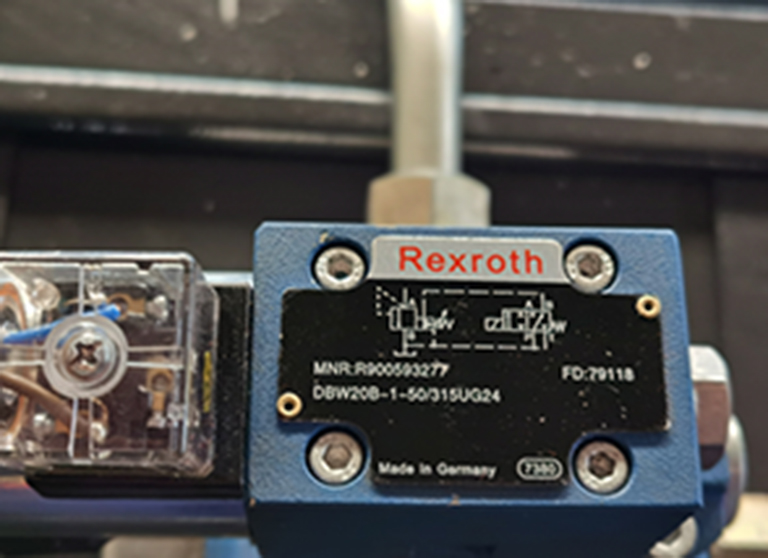

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:320mm | CNC or CN: CNC controller system |

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

Machine Details

Cyb Touch12 controller

● Large screen, high definition and contrast touch screen system.

● Convenient interface, clear display and large icon buttons.

● Intuitive and friendly human-machine interface.

● Perfect programming can make batch multi-step bending more efficient.

● EasyBend page single-step bending is very convenient.

● Online help and pop-up tips make the software interface very user-friendly.

● Wireless software upgrades and data transfer are possible using a PC or laptop.

● Supports multiple languages.

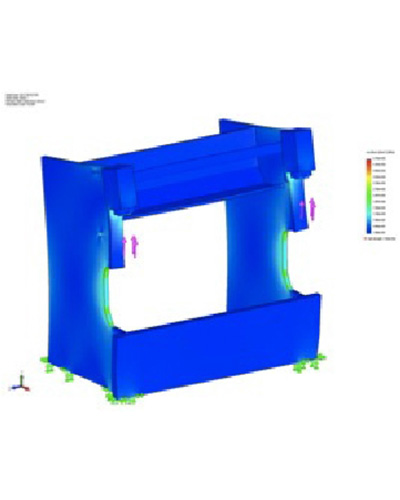

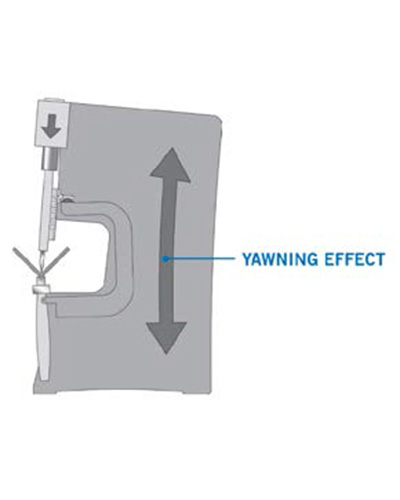

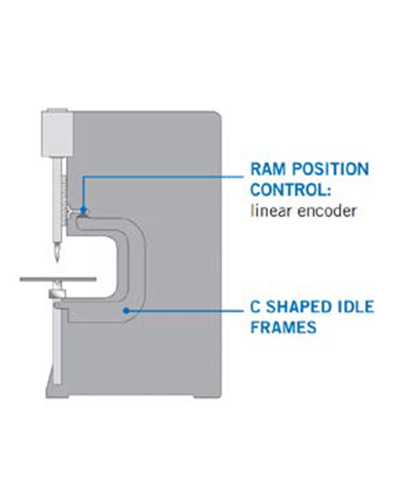

Overall welding

Overall welding the front workbench vertical plates and machine frames ensure there are no seam between vertical plates and bilateral wall plates.

■ Totally European streamlined design,Monoblock welded steel frame rigid & Heat Treated.

■ our machine designed according to the most modern design and performances point of view.

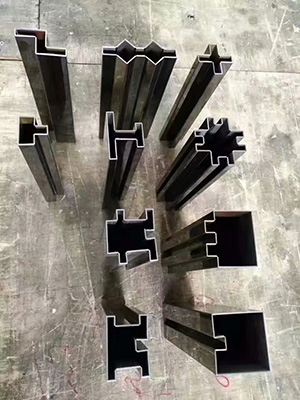

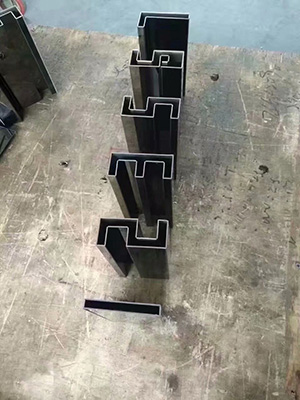

Moulds

Moulds can be optional, with high toughness, with long life, can bend high precision workpiece

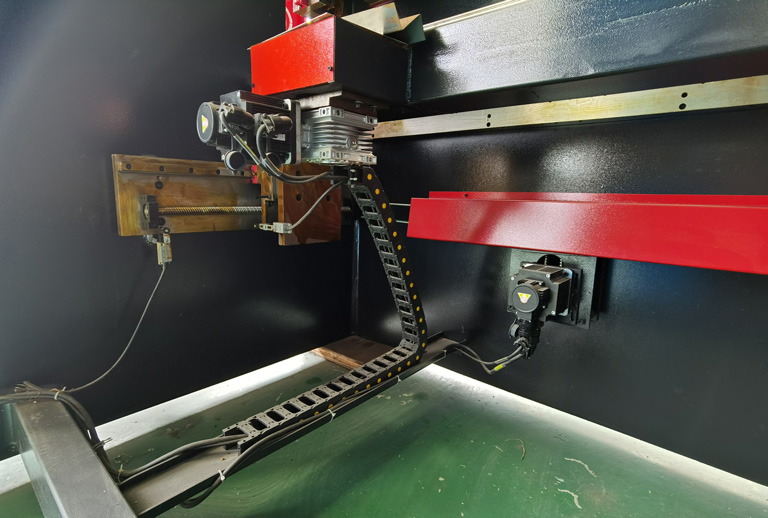

Ball screw and linear guide

with high precision, high efficient,high stability

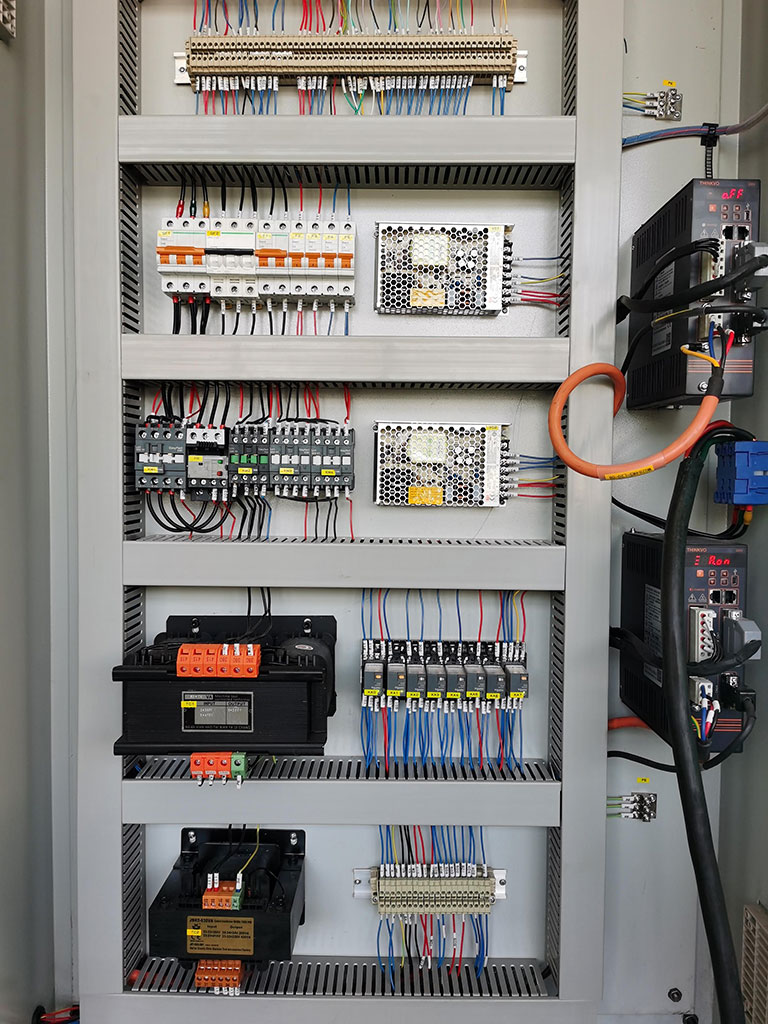

France Schneider electrics and DELTA inverter

Adopt france schneider electrics components,with high positioning accuracy

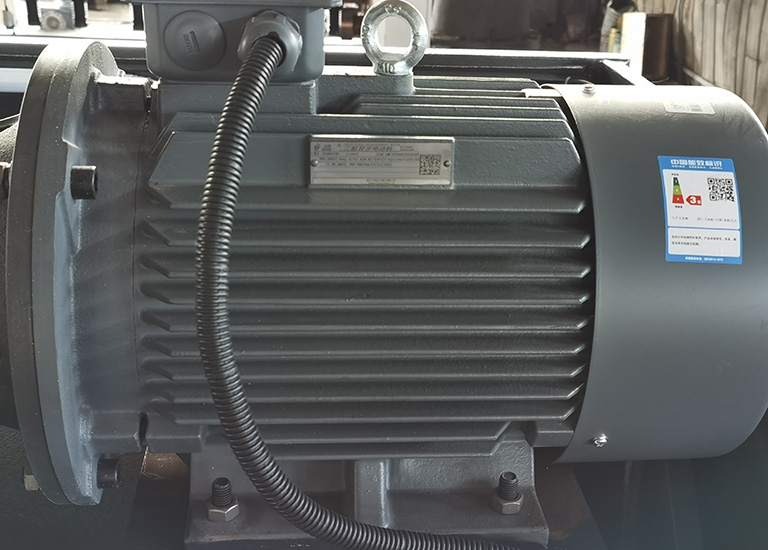

Siemens motor

Using siemens motor guarantee machine has long service life, can reduce nosie,with high stability

Sunny oil hydraulic pump

Using Sunny pump guarantees the oil service life, with low noise

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability,integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid

Quick clampings

Using mechanical fast clamp for fast replacement of top punch dies.

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction