Hydraulic Rolling Machine

-

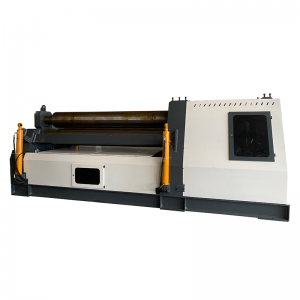

W12 -20 X2500mm CNC four roller hydraulic rolling machine

The hydraulic rolling machine has a compact and reasonable structure and is easy to operate. The metal plate passes through the three work rolls of the plate rolling machine, with the help of the lower pressure of the upper roll and the rotational movement of the lower roll, the metal plate is continuously bent in multiple passes, resulting in permanent plastic deformation, and rolled into cylinders, arcs, cones Tubes and other workpieces, with high machining accuracy and high work efficiency. The hydraulic rolling machine adopts an advanced integrated hydraulic system to ensure the high reliability of the plate bending machine hydraulic rolling machine in operation.

-

W11SCNC-8X3200mm CNC four roller hydraulic rolling machine

The hydraulic rolling machine has a compact and reasonable structure and is easy to operate. The metal plate passes through the three work rolls of the plate rolling machine, with the help of the lower pressure of the upper roll and the rotational movement of the lower roll, the metal plate is continuously bent in multiple passes, resulting in permanent plastic deformation, and rolled into cylinders, arcs, cones Tubes and other workpieces, with high machining accuracy and high work efficiency. The hydraulic rolling machine adopts an advanced integrated hydraulic system to ensure the high reliability of the plate bending machine hydraulic rolling machine in operation.

-

Top quality W11SCNC-6X2500mm CNC four roller hydraulic rolling machine

Rolling machine is a kind of equipment that rolls the sheet material by using work rolls. It can form different shapes such as cylindrical parts and conical parts. It is a very important processing equipment. The working principle of the plate rolling machine is to move the work roll through the action of external forces such as hydraulic pressure and mechanical force, so that the plate is bent or rolled into shape. According to the rotation movement and position change of work rolls with different shapes, parts such as oval parts, arc parts, and cylindrical parts can be processed.

-

Top quality W11SCNC-10X2500mm CNC four roller hydraulic rolling machine

The upper roller of the hydraulic four-roller hydraulic rolling machine can be vertically lifted and hydraulically driven, which is obtained by the action of the hydraulic oil in the hydraulic cylinder on the piston rod; the lower roller is driven by rotation and meshed with the output gear of the reducer to provide power for rolling the plate. There are idlers at the lower part of the lower roller, which can be adjusted. The hydraulic four-roll plate rolling machine can roll metal sheets into circular, arc and conical workpieces within a certain range.The moving modes of the hydraulic four-roller rolling machine are mechanical and hydraulic, and the drive shafts are connected by universal couplings.

-

Top brand W11S-10X3200mm three roller hydraulic cnc rolling machine

W11S-10X3200mm three roller hydraulic rolling machine can roll 10mm thickness, 3200mm length of metal sheet plates with high efficiency.The electric control system of the hydraulic rolling machine adopts PLC programmable controller, touch screen display, process parameters can be stored, simple operation and high efficiency.When the hydraulic plate rolling machine is working, the metal plate is placed between the upper and lower rollers, and the upper roller is pressed down, so that the metal plate is curled between the supporting points. The plate is evenly curled, and high-precision workpieces such as cylinders and cones are rolled.