High precision QC11Y-25X3200mm hydraulic guillotine shearing machine

Product Introduction

Macro factory best quality QC11Y-25X3200mm hydraulic guillotine shearing machine can cut 3200mm length of sheet metal plates, 25mm thickness of plates.The hydraulic guillotine shearing machine adjusts the blade gap according to the thickness of the sheared sheet, and the blade gap can be adjusted by adjusting the eccentric wheel structure, which is easy to operate.It is equipped with france schneider electric system,woking safety and realibility.The hydraulic system working with low noise,move smoothly and easy maintain.

Feature

1.With all welded construction

2.Hydraulic system and electric system working stable

3.With long life EMB tube

4.With world famous siemens motor, sunny oil pump

5.With high accuracy backguage

6.With spring pressing cylinder device

7.Blade clearance can be easily adjust

8.CNC controller system can be optional

Application

Hydraulic guillotine shearing machine are widely used in sheet metal manufacturing, aviation, light industry, metallurgy, chemical industry, construction, marine, automotive, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment.

Parameter

| Max cutting width(mm):3200mm | Max cutting thickness(mm):25mm |

| Automatic level: automatic | Condition: new |

| Brand name: Macro | Power(KW):37 |

| Voltage:220V/380V/400V/480V/600V | Warranty: 1 year |

| Certification: Ce and ISO | Key selling points: high efficiency and high accuracy |

| After sale service: free spare parts,field installation,commissioning and training,field maintenance and repair service,online and video technical support | Controller system: E21S |

| Applicable industries:Hotels,Machinery repair shops,construction works,energy and mining, | Electrical components: Schneider |

| Color: according customer choose | Valve: Rexroth |

| Sealing rings:Volqua Japan | Motor: Siemens |

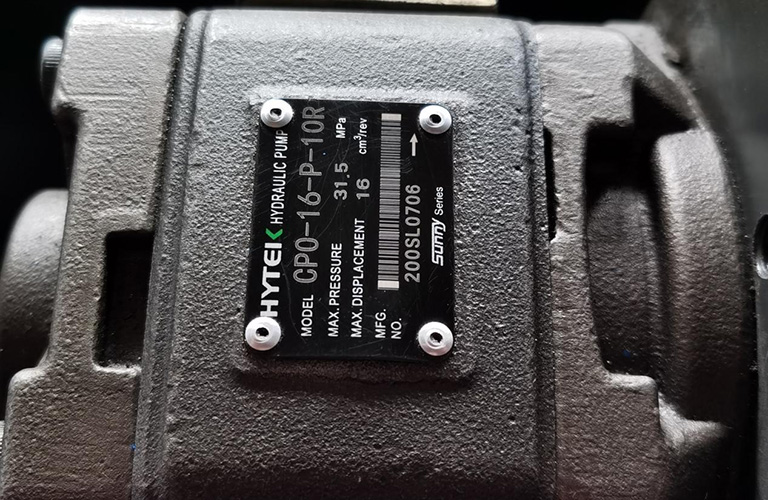

| Hydraulic oil: 46# | Pump: sunny |

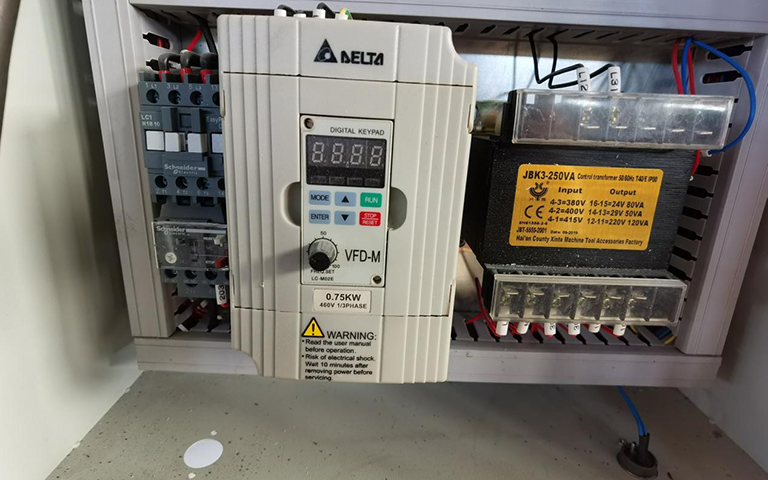

| Application: Mild carbon,stainless steel or iron sheet | Inverter: DELTA |

Machine Details

E21 NC controller

● One-way and two-way positioning function, effectively eliminate the lead screw gap

● 40 programs can be stored, each program has 25 steps

● One-click backup of parameters

● Back gauge positioning function

● Control motors and frequency converters

● Chinese-English 2 language

Blade clearance adjustment

Cutting thin and thick plates, can adjust blade clearance

Overall welding

With long life,high rigidity

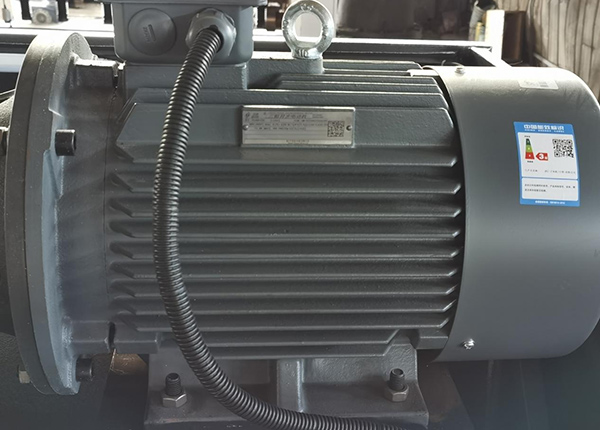

Siemens motor

Siemens motor easy operate, working stability

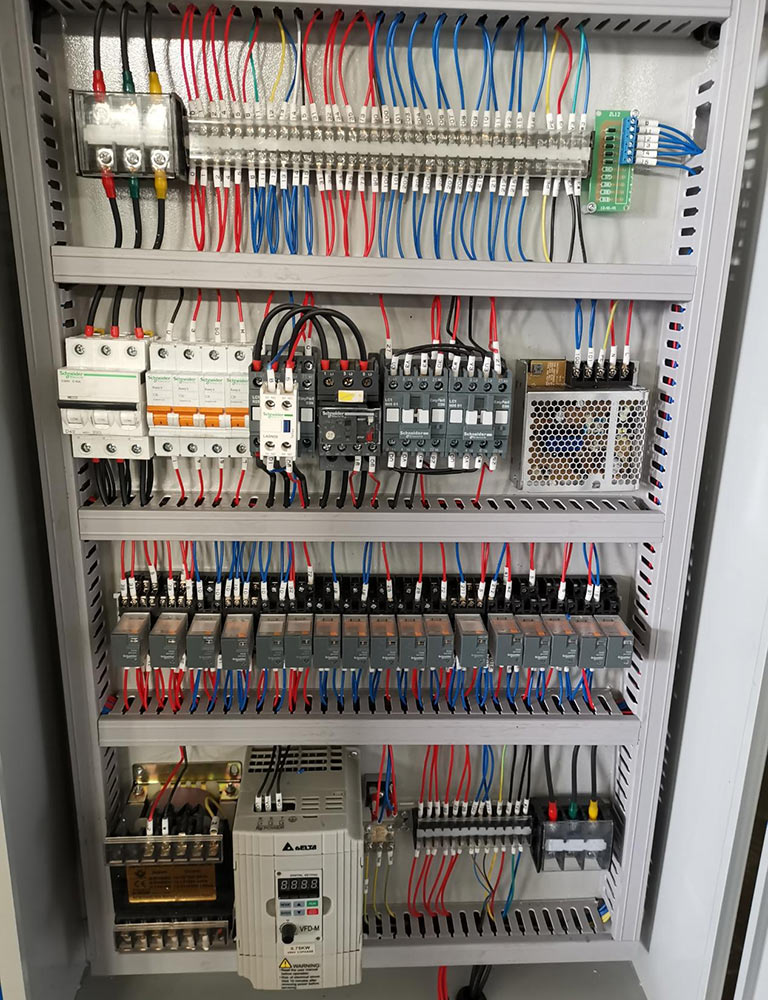

Schneider electrical components and DELTA inverter

Stable france schneider electrics components has strong anti-interference

America sunny oil pump

Equipped with best quality sunny oil pump

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Built in spring pressure cylinder

It can hold down plates when cutting plates