High precision four column 500Ton hydraulic press machine

Product Introduction

The 500T four-column hydraulic press machine is designed by computer three-dimensional finite element software, with high strength, good rigidity and beautiful appearance. The oil cylinder adopts a piston-cylinder structure, and can press out various high-precision workpieces by sliding the piston rod up and down. The oil cylinder is forged as a whole and processed by precision grinding, which is safe and reliable to use. The hydraulic press machine is mainly composed of a frame, a hydraulic system, a cooling system, a pressurized oil cylinder, an upper die and a lower die. The pressurized oil cylinder is installed on the upper end of the frame and is connected to the upper die. The utility model is characterized in that the lower end of the frame is provided with a mobile workbench, and the lower mold is mounted on the top of the mobile workbench. The hydraulic press machine adopts PLC programming circuit design, which has a high degree of intelligence and realizes digital control.

Feature

1. The hydraulic press adopts hydraulic transmission, equipped with imported professional integrated valve block, and has good sealing performance

2. The hydraulic system adopts professional oil circuit design with high precision

3. The electrical part adopts imported automatic control system, with strong anti-interference

4. The overall steel structure is adopted, with good stability and high strength

5. The oil cylinder adopts tandem oil cylinder, which improves the movement speed, high production efficiency and long life.

6. The hydraulic press has high safety and can realize one-time stamping and forming

Application

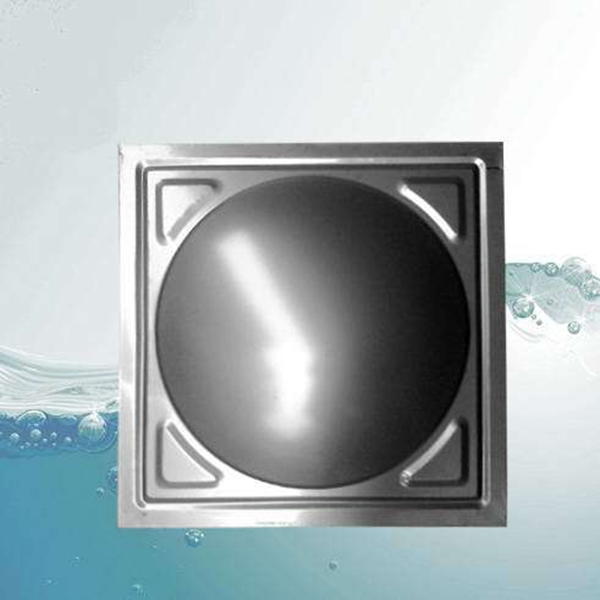

Hydraulic press machine are widely used, suitable for stretching, bending, flanging, forming, stamping and other processes of metal materials, and can also be used for punching, blanking processing, and are widely used in automobiles, aviation, ships, pressure vessels, chemicals, shafts Pressing process of parts and profiles, sanitary ware industry, hardware daily necessities industry, stainless steel product stamping and other industries.

Parameter

| Condition: new | Normal force(KN): 500 |

| Machine type: hydraulic press machine | Voltage:220V/380V/400V/600V |

| Power source: hydraulic | Key selling points:high effciency |

| Brand name: Macro | Color: customer choose |

| Motor power(KW):37 | Kye word: steel door hydraulic press |

| Weight(Ton):20 | Function: sheet metal embossing |

| Warranty: 1 year | System:servo/normal optional |

| Applicable industries:hotels, building meterial shops,machinery repair shops,construction works,building industry,decoration industry | After warranty service: online support,video technical support,field maintenance and repair service |

| Place of origin: jiangsu, china | Usage: press steel door, steel plate |

| Certification: CE and ISO | Electrical component: Schneider |