Hydraulic CNC Press Brake Machine

-

CNC Delem DA53T 4+1 axis WE67K-200T/4000mm hydraulic press brake machine

The electro-hydraulic servo CNC bending machine is equipped with a grating ruler. The electro-hydraulic proportional servo valve ensures the synchronous action of both sides of the slider and ensures the bending accuracy of the workpiece. The CNC system, electro-hydraulic proportional servo valve and grating ruler constitute the closed-loop control of the electro-hydraulic servo CNC hydraulic press brake machine. The electro-hydraulic synchronous CNC hydraulic press brake machine can control the speed of the sliding block to descend, the switching between the speed and the slow speed is convenient, and the back gauge runs quickly, which greatly improves the production efficiency of the bending workpiece.

-

CNC Delem DA53T 6+1 axis WE67K-160T/4000mm hydraulic press brake machine

Electro-hydraulic servo CNC bending machine can bend metal sheets of different thicknesses with high efficiency and high precision. The fuselage, slider and other important parts of the CNC bending machine are analyzed by ANSYS finite element analysis software to ensure the stability of machine performance. The CNC bending machine has high strength, good rigidity, stable operation, and high precision of the workpiece for bending, which is suitable for the industrial production demand for the increasing precision of the workpiece.

-

CNC Cyb Touch12 controller 4+1 axis WE67K-125T/3200mm hydraulic press brake machine

The fully automatic CNC electro-hydraulic servo CNC press brake machine has high workpiece bending accuracy and can improve work efficiency. The whole steel plate of the machine adopts integral welding, and the machine tool has high stability and high strength. Equipped with Cyb Touch12 CNC system imported from Switzerland and 4+1 axies to realize efficient multi-angle programming, simple operation and improve work efficiency. The double cylinder of the CNC press brake machine adopts electro-hydraulic synchronous control, the positioning accuracy of the back gauge is high, and it is equipped with imported laser photoelectric protection, which can process various high-precision sheet metal workpieces.

-

High efficiency Delem DA66T controller 6+1 axis WE67K-100T/2500mm hydraulic press brake machine

Automatic CNC hydraulic press brake machine can bend all thickness of metal sheet stainless steel plates with high accuracy.CNC hydraulic bending machine adopts Delem DA66T controller system, easy to program, operate and control. It is equipped with 6+1 axis,include Y1、Y2、X、R、Z1、Z2、W axis, can bend plates with high precision. It adopts Electro-hydraulic servo motor, and add deflection compensation deviceCNC hydraulic press brake machine can angle compensation, length compensation and gap error compensation are possible,can guarantee the accuracy of the workpiece

-

CNC automatic 8+1 axis delem DA66T WE67K-63T/1600mm hydraulic press brake machine

CNC hydraulic press brake machine adopts all-steel welded structure, which has good rigidity and stability. Equipped with the Delem DA66T CNC controller system imported from the Netherlands delem company, it can realize automatic programming and bending simulation, and improve the bending accuracy of sheet metal.By configuring different molds, the CNC bending machine can bend workpieces of various shapes with high precision.

-

CNC Delem DA66T 6+1 axis WE67K-300T/4000mm hydraulic press brake machine

The frame of the full CNC electro-hydraulic servo bending machine adopts a new rigid design, and the frame adopts a steel plate integral welded structure to eliminate internal stress and ensure the overall high precision of the machine tool, so that the bent workpiece has a high straightness. Equipped with German Rexroth electro-hydraulic proportional servo synchronous control system, the synchronizing error of the slider can be detected through the grating ruler, thus ensuring the high synchronization accuracy of the slider. The CNC hydraulic press brake machine is equipped with a slow return function, and the operator can better control the bending speed of the workpiece to ensure that each workpiece is bent with high precision.

-

CNC Cyb Touch12 controller 4+1 axis WE67K-125T/4000mm hydraulic press brake machine

The full CNC electro-hydraulic servo CNC bending machine adopts finite element mechanical analysis to ensure that the frame has the optimal size, thereby ensuring that the frame has high rigidity, high overall stability and high precision. Equipped with high-efficiency and high-precision back gauge positioning system, the back gauge is quickly positioned, and the slider runs at high speed, which greatly improves the bending efficiency. The CNC hydraulic press brake machine is equipped with imported hydraulic system, Siemens motor and oil cylinder with long service life, low noise and green bending.

-

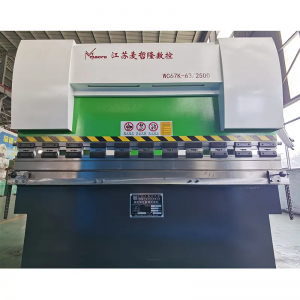

CNC automatic 8+1 axis delem DA66T WE67K-63T/2500mm hydraulic press brake machine

The fully automatic electro-hydraulic synchronous CNC hydraulic bending machine is equipped with 8+1 axes, and the machine tool synchronization is controlled by closed-loop electro-hydraulic proportional servo system to perform bending, and the bending accuracy is high. The CNC hydraulic press brake machine has sufficient strength and rigidity, and the whole steel plate is welded to ensure parallelism and perpendicularity. The CNC hydraulic press brake machine adopts hydraulic transmission, which has stable operation and high reliability.