High precision QC12Y-8X4000mm hydrauclic sheet metal shearing machine

Product Introduction

The hydraulic pendulum shearing machine is a hydraulically driven shearing machine, which relies on the rotation of the tool holder to cut various metal plates. The hydraulic swing beam shearing machine performs downward shearing motion through the main oil cylinder and the nitrogen cylinder returns, and the operation is stable. The upper tool rest of hydraulic shearing machine swings in an arc around a fixed axis during the shearing process. The stroke of the upper tool rest can be adjusted. The machine has a compact structure, long service life and high work efficiency.

Feature

1.Steel plate welded structure, hydraulic transmission, nitrogen cylinder return

2.Equipped with Eutun E21 controller system,easy operation, reliable performance, beautiful appearance

3.Equipped with safety protection fence to ensure safety

4.Easy blade clearance adjustment, with high precision

5.Hydraulic shearing machine blades have a long service life

6.Back gauge adjustment with high precision

7.Equipped with germany siemens motor, work stability

8.Cut plates smoothly,with high accuracy

Application

Hydraulic shearing machine are widely used in sheet metal manufacturing, aviation, light industry, metallurgy, chemical industry, construction, marine, automotive, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment.

Parameter

| Max cutting width(mm):4000mm | Max cutting thickness(mm):8mm |

| Automatic level: automatic | Condition: new |

| Brand name: Macro | Power(KW):11 |

| Voltage:220V/380V/400V/480V/600V | Warranty: 1 year |

| Certification: Ce and ISO | Key selling points: high efficiency and high accuracy |

| After sale service: free spare parts,field installation,commissioning and training,field maintenance and repair service,online and video technical support | Controller system: E21S |

| Applicable industries:Hotels,Machinery repair shops,construction works,energy and mining, | Electrical components: Schneider |

| Color: according customer choose | Valve: Rexroth |

| Sealing rings:Volqua Japan | Motor: Siemens |

| Hydraulic oil: 46# | Pump: sunny |

| Application: Mild carbon,stainless steel or iron sheet | Inverter: DELTA |

Machine Details

E21 NC controller

● Backgauge Control

● Control common motors or inverters, intelligent positioning

● Programmable digital output, workpiece count

● 40 program storage, 25 steps per program

● Unilateral positioning, retreat function

● One-key backup and restore of parameters

● Metric and English; Chinese and English

Blade clearance adjustment

Fast and flexible gap adjusting mechanism,have high shearing accuracy

Overall welding

Overall welding has high rigidity,high precision

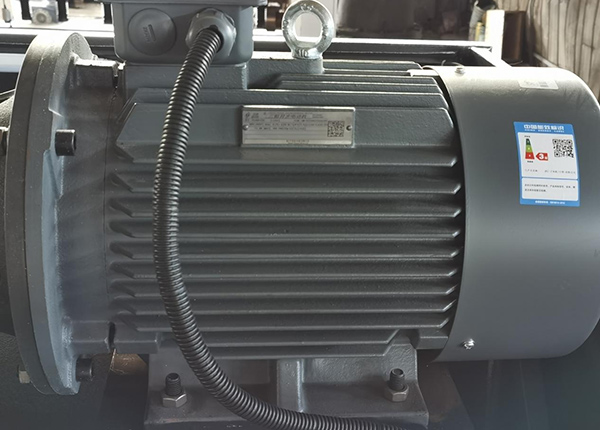

Siemens motor

Imported germany siemens motor to reduce noise, working stability

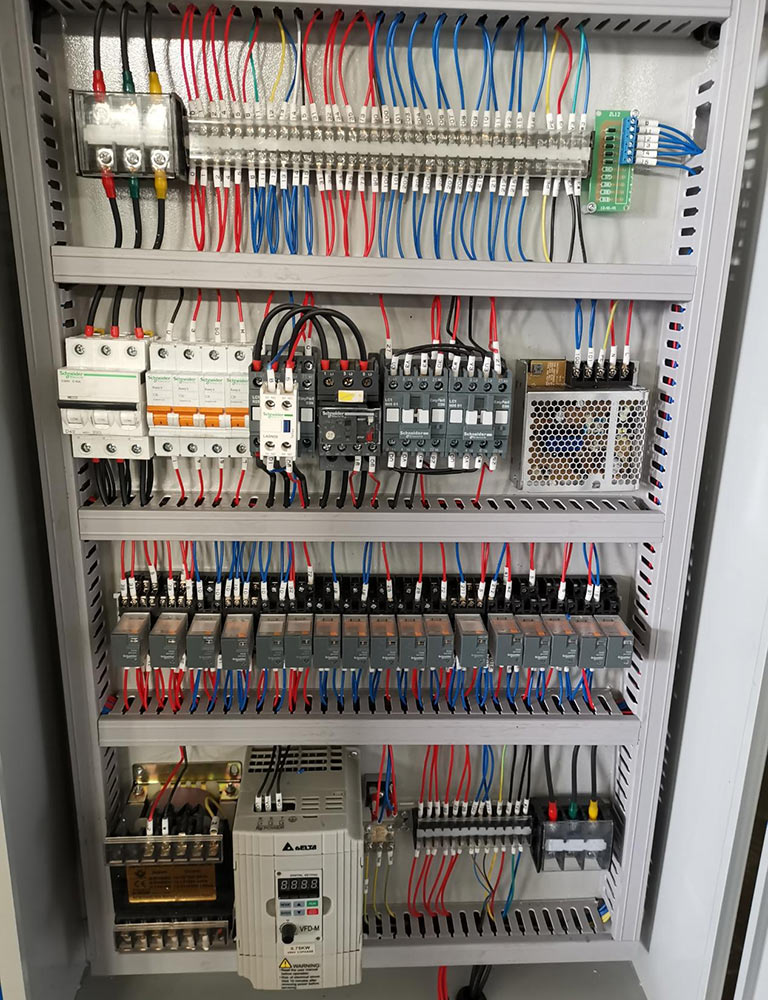

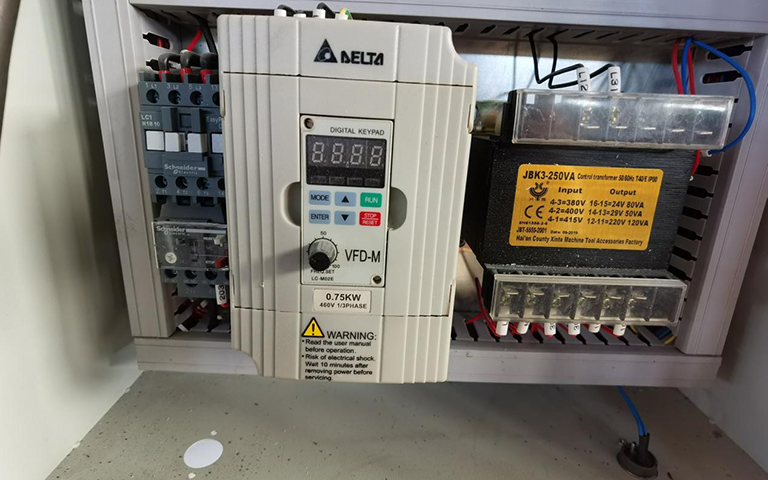

Schneider electrical components and DELTA inverter

Schneider electric components ensure working stability,high quality,good perfomance

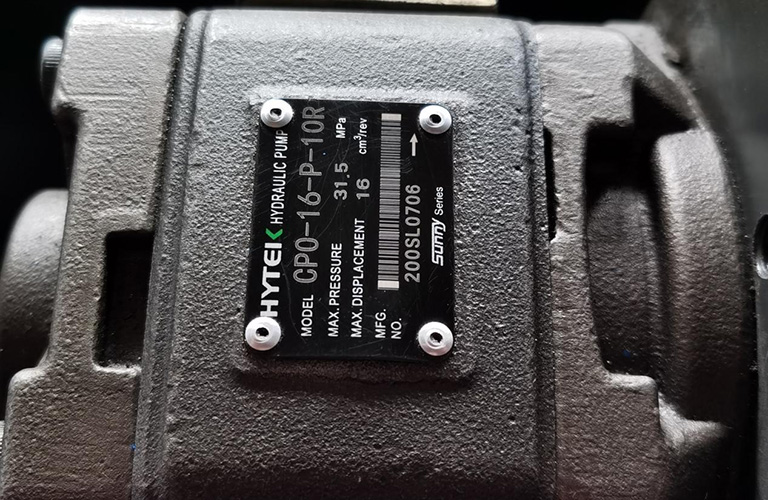

America sunny oil pump

Sunny oil pump with precise pressure control

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Built in spring pressure cylinder

Separately control the pressure,working stability