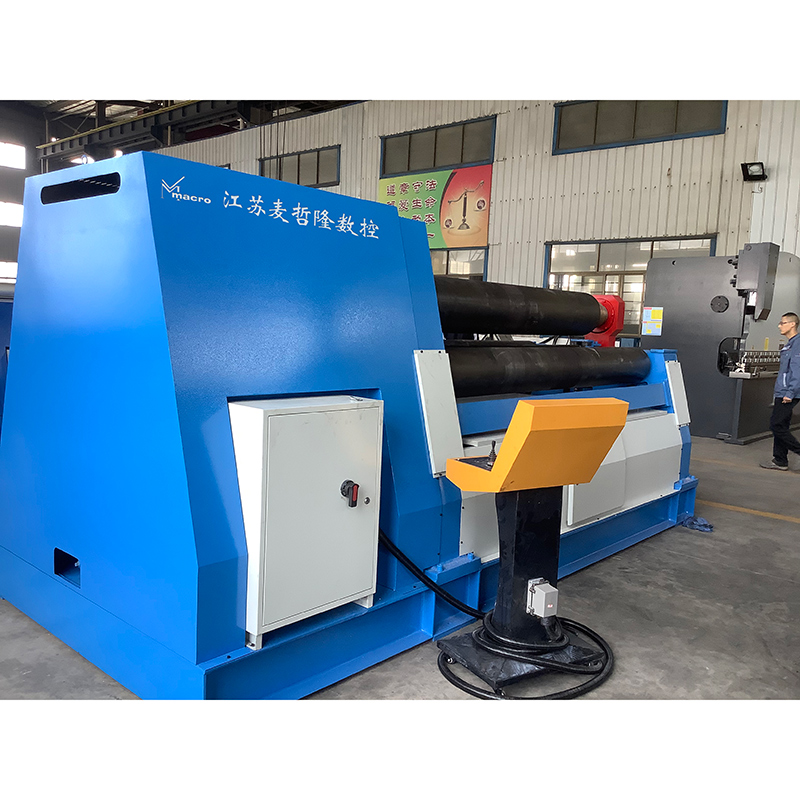

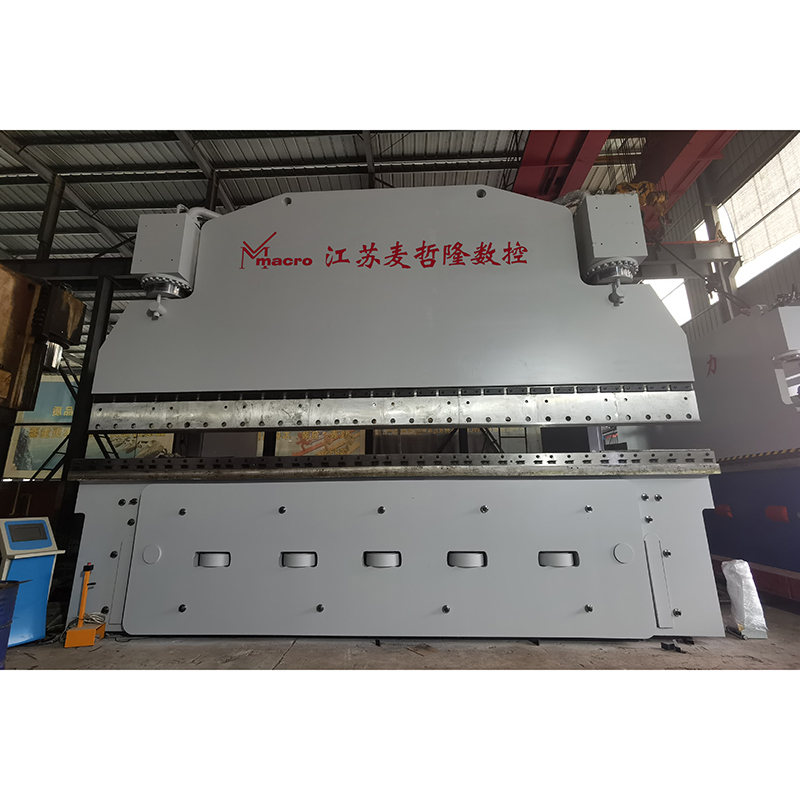

Factory Promotional 102 Press Brake Machines - WE67K-2X1200T/8000mm CNC ESA S630 controller tandem hydraulic press brake bending machine – Macro

Factory Promotional 102 Press Brake Machines - WE67K-2X1200T/8000mm CNC ESA S630 controller tandem hydraulic press brake bending machine – Macro Detail:

Product Introduction

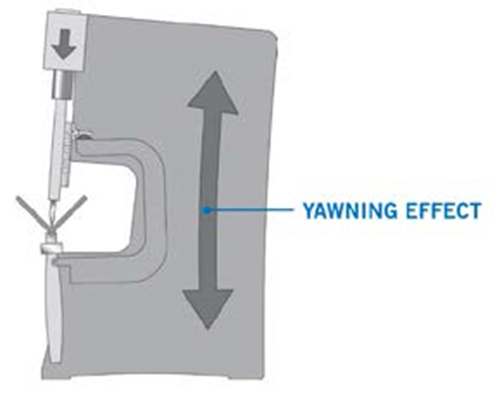

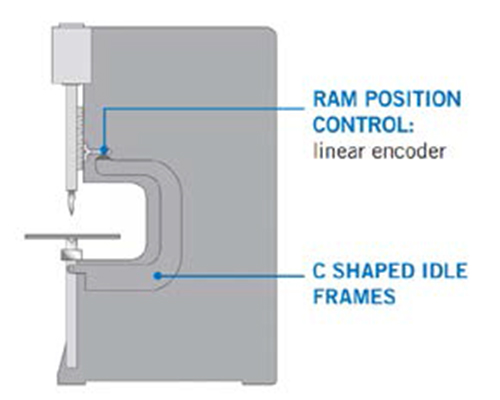

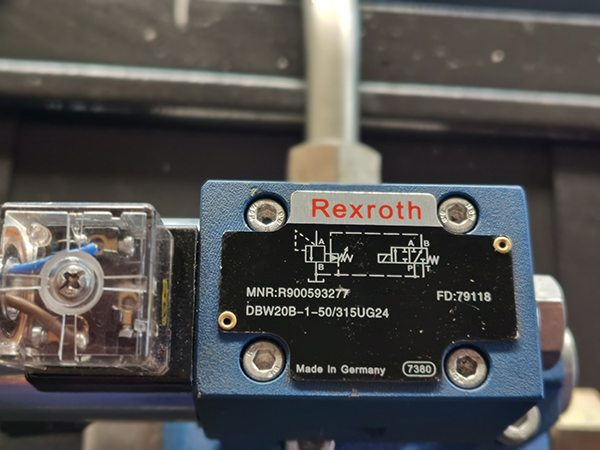

The double-machine linkage bending machine can be specially customized according to the size of the workpiece processed by the customer, such as opening height, slider stroke, throat depth, back gauge stroke, etc.Each machine in the CNC tandem hydraulic press brake machine can also be used independently increasing flexibility.Equipped with a compensation system, the compensation is automatically adjusted by the numerical control system, which is convenient and accurate, ensuring the straightness and bending accuracy of the bending workpiece, and the workpiece can be bent at various angles and shapes. The integrated hydraulic system and imported Bosch rexroth valve can effectively reduce noise and prolong service life. Equipped with large customized upper and lower molds with high hardness, durable and reliable. Equipped with 2 ESA S630 CNC systems, high resolution display, built-in PLC function, automatic programming and bending simulation.

Feature

1.With closed-loop electro-hydraulic servo control technology

2.With 6+1 axies cnc axies,Italy esa s630 controller system

3.Use mechanical compensation or hydraulic compensation device

4.With high reliability france schneider electric components

5.With imported servo motor, siemens motor

6.With totally EU streamlined design,high strength structure

7.With high quality ball screw and liner guide

8.Moulds can be customized according workpiece size

Application

Hydraulic tandem press bake bending machine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic tandem bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, street light poles, power poles, wire lamp poles, new energy,stainless steel products and other industries.

Parameter

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):2X8000mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):12000KN |

| Motor Power(kw):2X75KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:500mm | CNC or CN: CNC controller system |

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

Samples

Machine Details

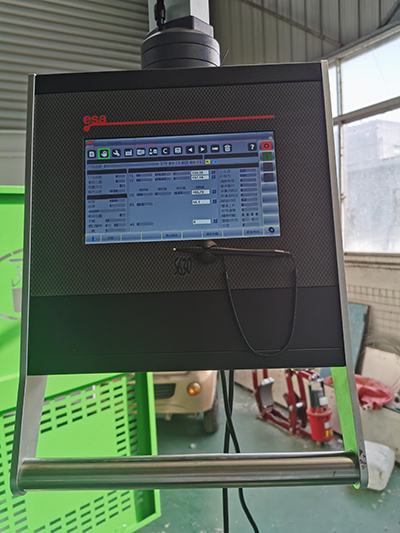

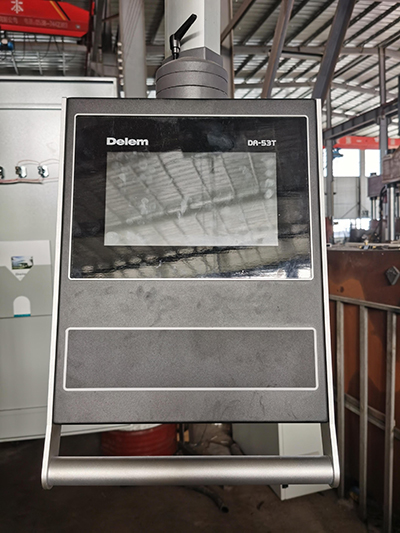

ESA 630 controller

● Support touch screen operation, high-definition 10-inch touch screen

● Built-in PLC

● 2D graphics programming, expansion length calculation

● Graphical upper and lower molds, support polygon molds, telescopic molds, arc molds, gooseneck molds and other molds

● Automatic and manual optimization of graphic programming, support for simulated bending

● Support graphic or numerical arc bending, support dual-machine linkage function

● Standard 4+1 axis

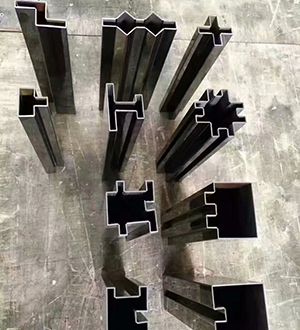

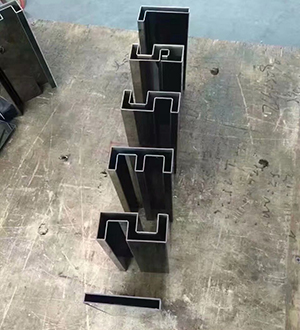

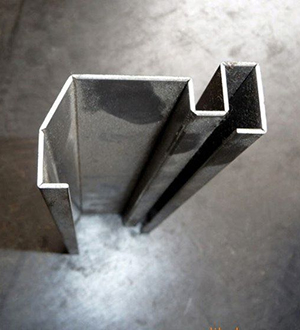

Moulds

With long lifespan,multiple moulds can be choosed

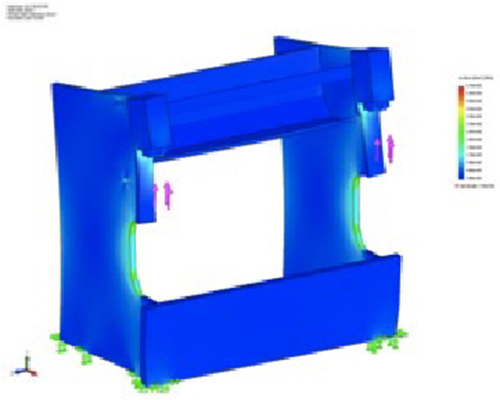

Overall welding

With high precision overall welding,designed according workpiece

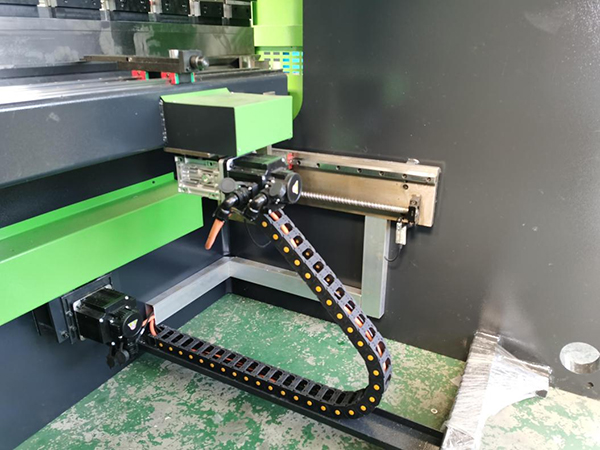

Ball screw and linear guide

Can improve bending accuracy

Siemens motor

Using Siemens motor can provide stable power for hydraulic system

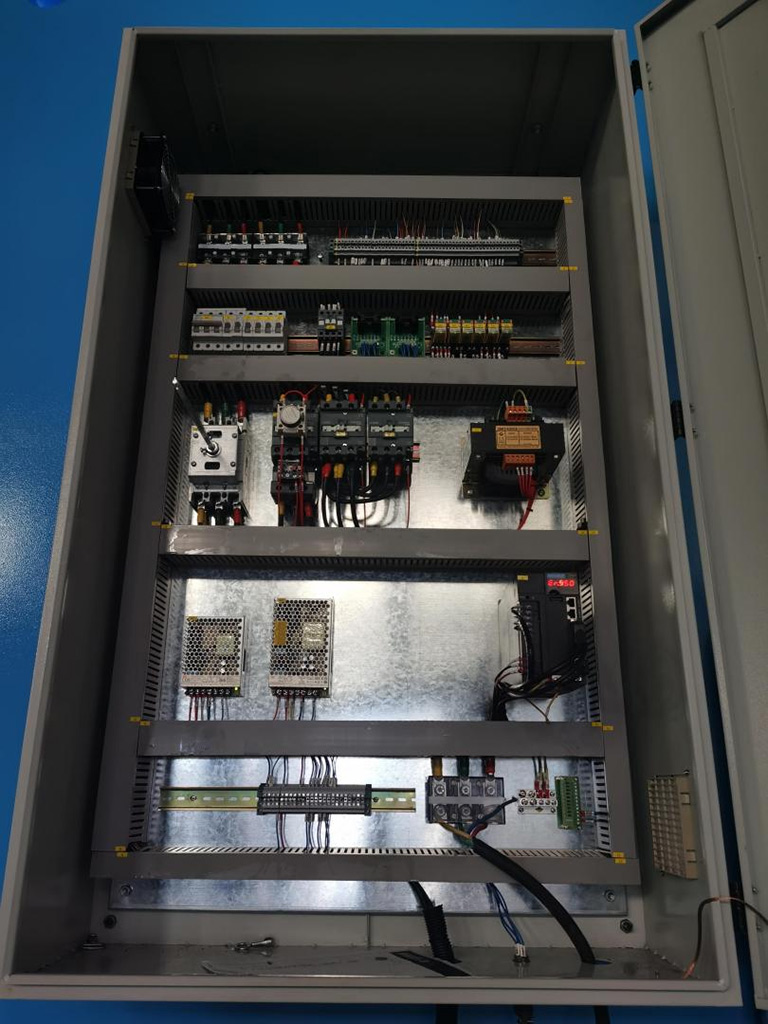

France Schneider electrics and DELTA inverter

france schneider electrics with cost-effective, safe and reliable

Sunny pump

Sunny oil pump can control pressure with high precision

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction

Quick clampings

Quick clampings can change moulds easily.

Optional controller system

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Factory Promotional 102 Press Brake Machines - WE67K-2X1200T/8000mm CNC ESA S630 controller tandem hydraulic press brake bending machine – Macro , The product will supply to all over the world, such as: Bahrain, Detroit, Vancouver, Our mission is "Provide Goods with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!