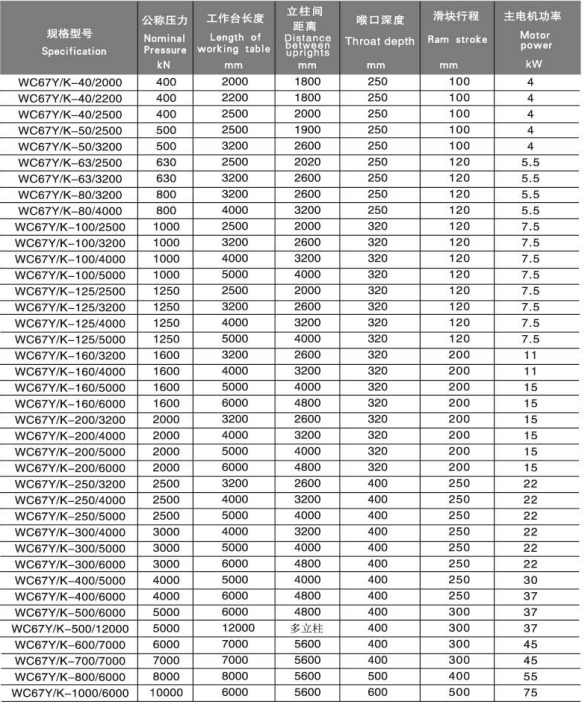

Macro high quality WC67Y hydraulic 80T 2500 NC press brake machine

Product introduction:

The frame of the hydraulic bending machine is processed after welding to ensure high strength, high precision and high rigidity. The mechanical synchronization system is adopted, and the two sides of the slider are moved in parallel through the synchronization shaft. Equipped with upper mold deflection compensation device, and optional fast upper mold clamping device. The back gauge of the hydraulic press brake machine has high precision, and the adjustment includes electric quick adjustment and manual fine adjustment, and the operation is simple. The X-axis back gauge is driven by siemens motor, driven by a ball screw, guided by a linear guide rail, and the stroke of the Y-axis slider is controlled by siemens motor to ensure high positioning accuracy. The configured Estun E21 controller system can efficiently control the operation of X-axis and Y-axis to ensure high bending accuracy.

Product feature

1.With high performance Estun E21 controller system

2.Equipped with high-strength all-steel welded structure

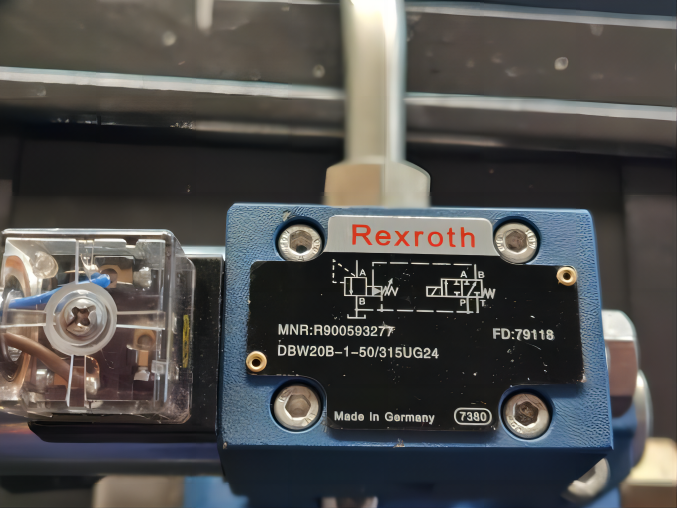

3.With germany bosch rexroth valve hydraulic system

4.Standard moulds, specialized moulds can be choosed

5.With stability schneider electric components

6.High-precision back gauge accurately locates the X-axis

7.With best quality siemens motor,sunny oil pump

8.Satisfy ISO/CE high standard

Product application

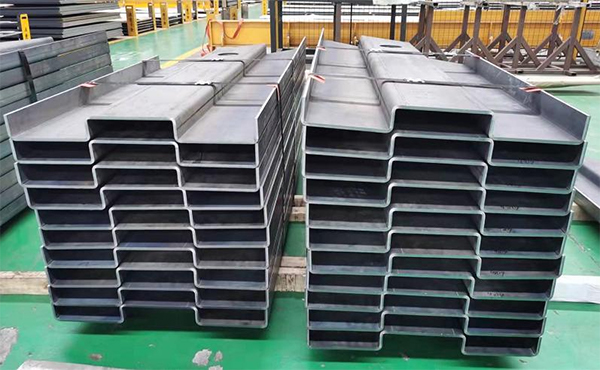

Hydraulic press bake bending machine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.