Factory wholesale Sheet Cutting Machine Price - Top brand W11S-10X3200mm three roller hydraulic cnc rolling machine – Macro

Factory wholesale Sheet Cutting Machine Price - Top brand W11S-10X3200mm three roller hydraulic cnc rolling machine – Macro Detail:

Product Introduction

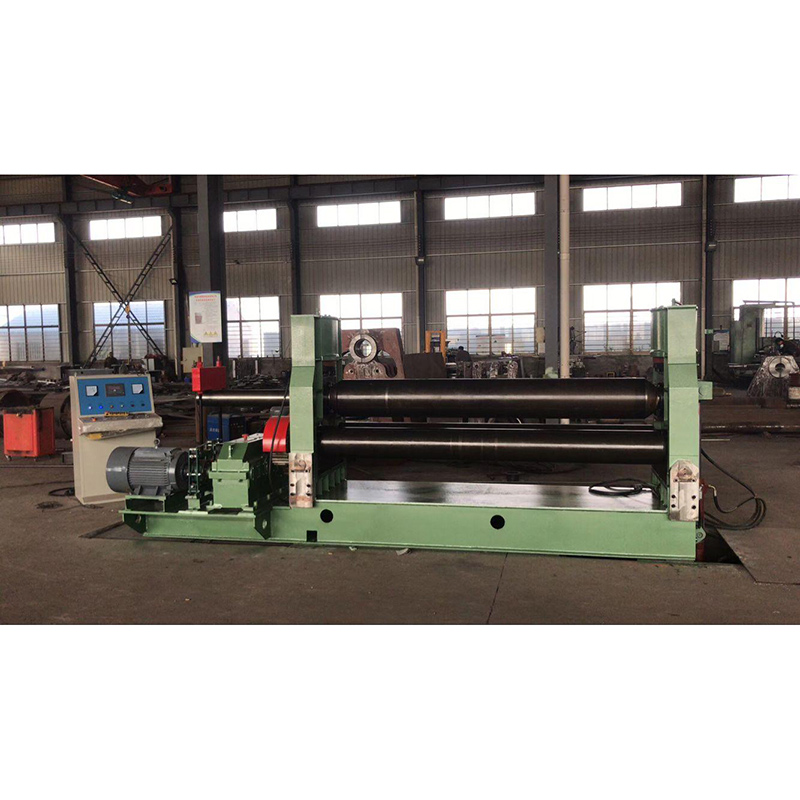

The hydraulic plate rolling machine is simple in operation and high in rolling precision. It is mainly composed of upper roller device, horizontal moving device, lower roller device, idler device, main transmission device, tipping device, hydraulic system and electric control system. The hydraulic plate rolling machine is equipped with a movable Siemens CNC system console, which is controlled by a PLC programmable display, and is equipped with a safety interlock device, which is convenient and safe to operate. The upper work roll of the hydraulic rolling machine is the main executive element of the equipment, which has sufficient strength, rigidity and precision to ensure the reliability and service life during operation.

Feature

1.Full hydraulic drive, High efficiency and energy saving

2.Equipped with CNC control system,high quality PLC control

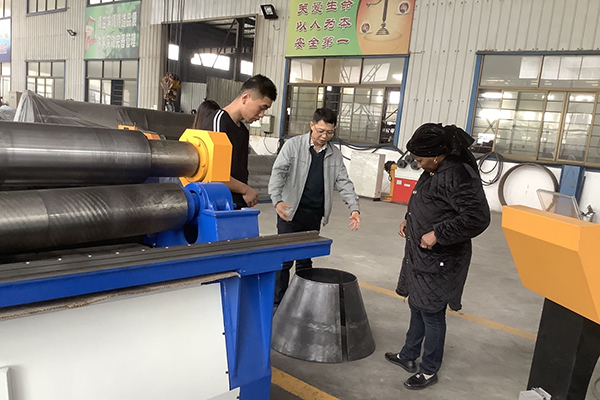

3.Cone bending device for roll conical easily

4. The Machine designed based on Germany Technology.

5.Pre-bending, rolling and round calibration can be completed in one pass

6.With ISO/CE high standard

Application

The rolling machine has a wide range of applications, and can be used in the fields of machinery manufacturing such as Aviation, ships, boilers, hydropower, chemicals, pressure vessels, electrical appliances, machinery manufacturing, metal processing and other industries.

Parameter

| Material/Metal processed:Aluminum,carbon steel,sheet metal,rion plate,stainless steel | Max working length(mm):3200 |

| Max plate thickness(mm): 10 | Condition:new |

| Place of origin: jiangsu,china | Brand name:Macro |

| Automatic: automatic | Warranty: 1 year |

| Certification: CE and ISO | Product name:4 roller rolling machine |

| Machine type: roller-bending machine | Max rolling thickness(mm): 10 |

| After sale service:online support,video technical support,field maintenance and repair service | Voltage:220V/380V/400V/600V |

| Plate yield limit:245Mpa | Controller: siemens controller |

| PLC:Japan or other brand | Power: mechanical |

Samples

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Factory wholesale Sheet Cutting Machine Price - Top brand W11S-10X3200mm three roller hydraulic cnc rolling machine – Macro , The product will supply to all over the world, such as: Turin, Swedish, Bhutan, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we'll build a better tomorrow!

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!