Factory making 101 Sheet Bending Machine Price - Top quality W11SCNC-10X2500mm CNC four roller hydraulic rolling machine – Macro

Factory making 101 Sheet Bending Machine Price - Top quality W11SCNC-10X2500mm CNC four roller hydraulic rolling machine – Macro Detail:

Product Introduction

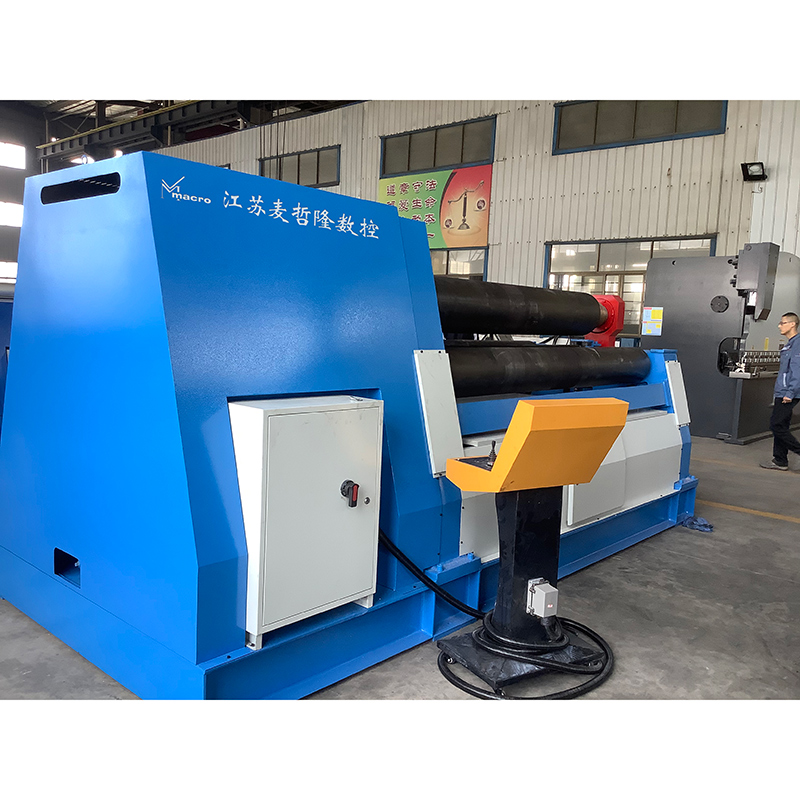

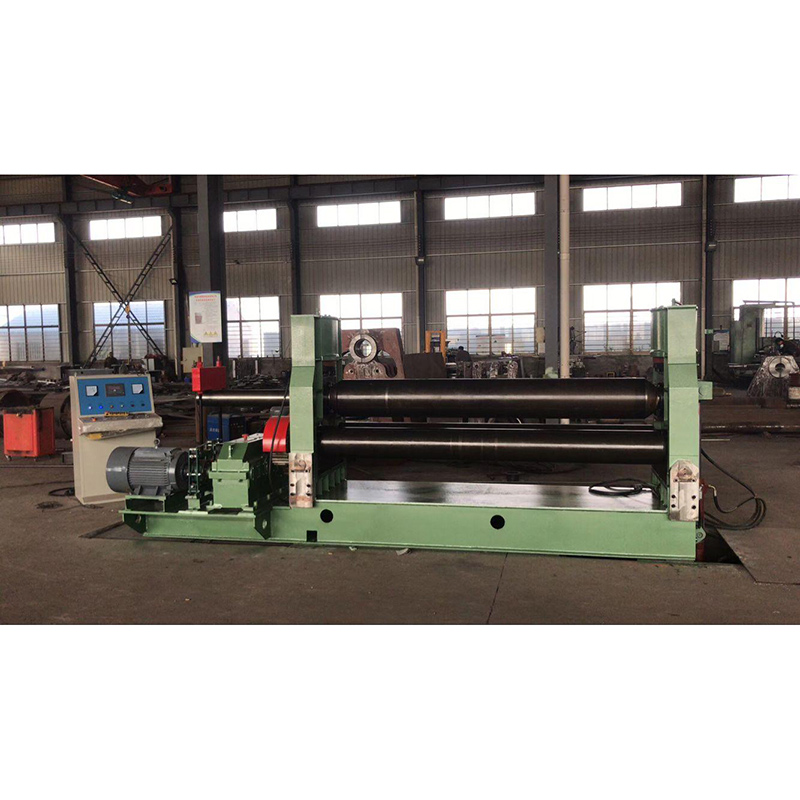

The CNC four-roller hydraulic bending machine is equipped with a programmable Siemens CNC system, which can store the automatic rolling/ bending data of hundreds of different workpieces, realize one-key calling, one-key start, simple operation and high precision. The CNC four-roll plate rolling machine not only satisfies the automatic plate rolling process of circle, but also meets the automatic plate rolling process of various arc, square, triangle, oblate, ellipse and other workpieces, and the workpiece processing precision is high. Imported hydraulic system and electric control system are adopted, and the control circuit is controlled by PLC programmable controller to ensure smooth operation of the plate rolling machine, convenient operation and long service life.

Feature

1.The whole frame is welded sturdy and durable, and the accumulator is used for a stable return

2.Adopt imported siemens motor and sunny oil pump from USA

3.Hydraulic system adopt germany Bosch – Rexroth,working stability

4.imported schneider electric components from france

5.with programmable logic controller PLC

6.Material of work roller with 42CrMo Alloy steel, roll plates with high efficiency

Application

The rolling machine has a wide range of applications, and can be used in the fields of machinery manufacturing such as Aviation, ships, boilers, hydropower, chemicals, pressure vessels, electrical appliances, machinery manufacturing, metal processing and other industries.

Parameter

| Material/Metal processed:Aluminum,carbon steel,sheet metal,rion plate,stainless steel | Max working length(mm):2500 |

| Max plate thickness(mm):10 | Condition:new |

| Place of origin: jiangsu,china | Brand name:Macro |

| Automatic: automatic | Warranty: 1 year |

| Certification: CE and ISO | Product name:4 roller rolling machine |

| Machine type: roller-bending machine | Max rolling thickness(mm):10 |

| After sale service:online support,video technical support,field maintenance and repair service | Voltage:220V/380V/400V/600V |

| Plate yield limit:245Mpa | Controller: siemens controller |

| PLC:Japan or other brand | Power: mechanical |

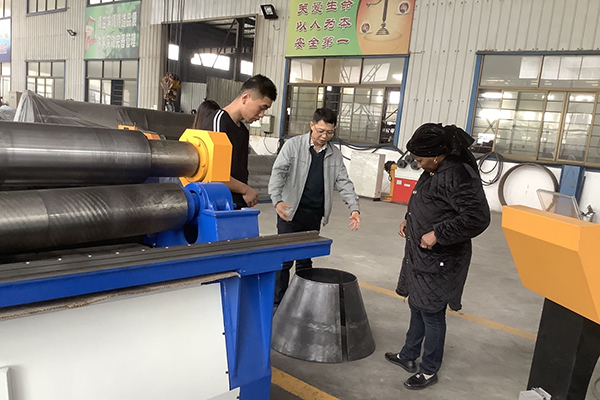

Samples

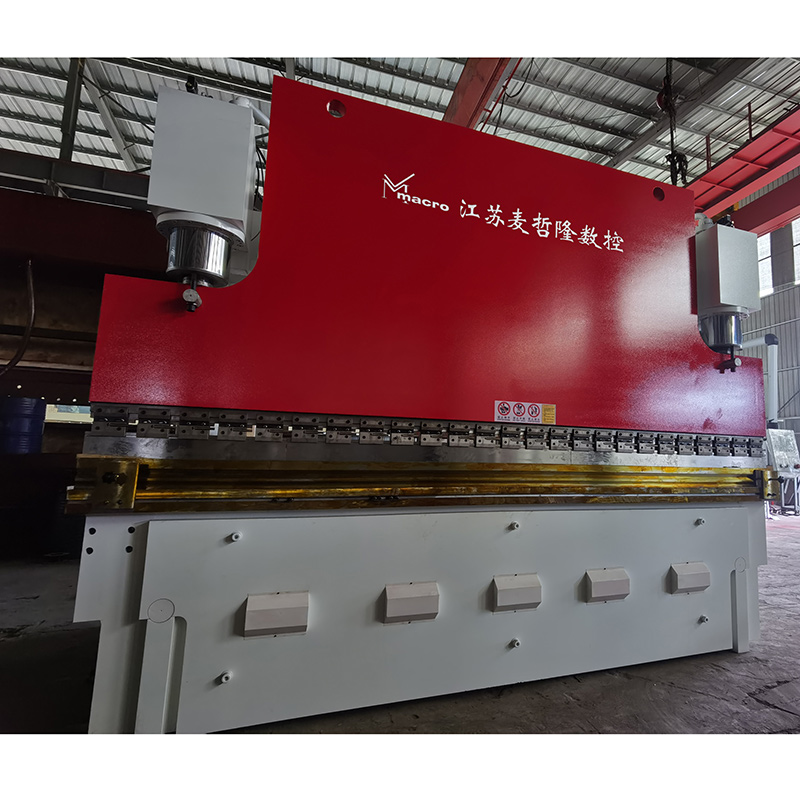

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory making 101 Sheet Bending Machine Price - Top quality W11SCNC-10X2500mm CNC four roller hydraulic rolling machine – Macro , The product will supply to all over the world, such as: Lithuania, Zimbabwe, Canada, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.