Sheet metal fabrication is an essential part of many industries, including aerospace, automotive and construction. In the past, producing high-quality, intricate sheet metal parts required skilled craftsmen to carefully shape the metal by hand. However, the development of press brakes has revolutionized sheet metal manufacturing, allowing for faster and more accurate production.

Bending machines are tools specifically designed to bend, fold and form sheet metal into various configurations. It works by applying force to a metal sheet and bending it into the desired shape. Bending machines can handle a wide variety of materials, including aluminum, stainless steel, and various types of steel.

Bending machines have many advantages. First, they significantly speed up production time, reducing the time needed to produce sheet metal parts from hours to minutes. This is due to the machines' ability to bend and shape sheet metal parts quickly and accurately.

Another advantage of press brakes is that they provide consistent, repeatable results. Unlike hand forming, which can result in variations in the finished product, press brakes produce the same part every time, which is critical in an industry where precision is paramount.

Bending machines also offer greater versatility than traditional hand forming methods. They can be programmed to bend and shape sheet metal in numerous ways, allowing for the easy production of complex parts.

Finally, press brakes are safer than hand forming methods. They are equipped with safety features such as safety guards and emergency stop switches to help prevent accidents in the workplace. With the growing demand for high-quality sheet metal products, press brakes are gaining popularity in sheet metal fabrication facilities. They are vital tools that help manufacturers produce parts faster, more accurately and with greater precision than ever before.

In conclusion, press brakes are revolutionizing sheet metal manufacturing, providing manufacturers with faster, safer, and more accurate methods of producing high-quality sheet metal parts. As the industry's demand for precise, complex sheet metal components continues to increase, press brakes will continue to be an important tool in the manufacturing process.

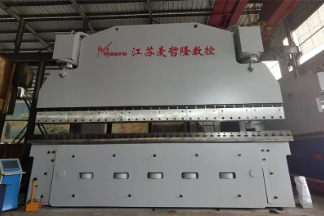

Our company also has many of these products.If you are interested, you can contact us.

Post time: Jun-07-2023